WHAT IS IIoT?

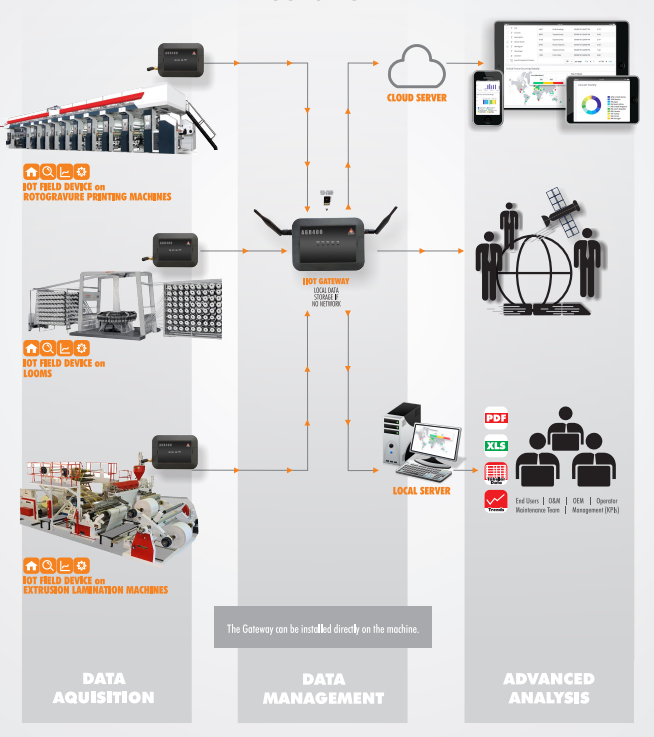

The Industrial Internet of Things (IoT) is connecting industrial machineries and equipments to the internet using microchips and sensors. This is enabling machineries to exchange data and communicate with each other. And when it comes to Plastic Print & packaging industries, IIoT is expected to transform them completely by empowering manufacturers to track and measure every element of their operations.

IIoT has become one of the most innovative technologies of this era. Using low-cost computing, the cloud, big data, analytics, and mobile technologies, Machineries can share data without much human interference. Each of the machines will be able to record, monitor, and adjust the flow of information, thereby merging the physical world with the digital one.

WHY IIoT?

For plastic, print- packaging and woven sack industry, one of the most promising technologies is the internet of things (IoT), which enables the digitization of internal processes, products, services and business models.

As these industries employs a lot of machineries like Rotogravure printing machine, Lamination Machine, in Woven Sacks industry Looms, Tapelines and Extrusion machine etc. IIoT can be utilized in the industry to keep track of production efficiency, Energy consumption, proper utilization of equipments and to avoid unnecessary maintenance.

ALTEEM INSTRUMENTS –PACKAGING 4.0

For Plastic, printing & packaging manufacturers, the most common and important challenges are to regulate maintenance expenses and raw material wastage, and maximize productivity in order to provide the best quality products in the market. In order to do that, the manufacturer needs to:

Keep a constant check on the operational capacities of the various machines to ensure smooth functioning

Optimize the consumption of resources such as electricity, fuel, water, etc. to reduce wastage and minimize costs, and

Monitor product output regularly to improve volume of production as and when necessary.

Apart from this, essential aspects like the hourly production, Job time cycle, consumption of electricity, Job Planning, material in use, speed of operation, and so on also needs to be tracked for optimal results.

Applying the concept of IIoT in plastic, printing & packaging greatly streamlines all the processes related to Production and maintenance, resulting in overcoming the above mentioned challenges and giving the manufacturer full control over the production process.

INTRODUCING IIoT IN PLASTIC PRINT-PACKAGING INDUSTRY

Connectivity

Allowing users to log and analyze key performance indicators such as OEE, Alteem’s Dashboard Portal is at the heart of connected services. Showing historical data and generating reports, it allows users to gain insights to produce real operational improvements, and can be used remotely via Laptops and Smartphones.

Remote Monitoring

Remote Monitoring provides live and historical data on all connected machines, including average speeds, OEE, units produced, uptime, downtime, Energy consumption, Job planning, material consumption and much more. This data can then be used to improve operations and enhance productivity.

Downtime Tracking

Giving you the opportunity to drill down to the root causes of downtime, Downtime Tracking improves overall production efficiency, Monitoring errors and to avoid such occurrence in future.

- Detailed reports of machine events

- Job completion alerts

- Potential job registration/planning

- Customizable event-generation for easy monitoring

- Machine Live Mode for machine-specific monitoring

- Customizable alerts for desired events

- Production efficiency reports

- Energy consumption reports

- Customized dashboards for easy access

- Offline log facility

- Web as well as local network application

- Cross-Platform Mobile App

- Dynamic web application

- RS232 & RS485 connection facility

What IoT will do for you in your packaging process?

IIOT can be utilized in the industry to keep track of production efficiency, energy consumption, proper utilization of equipment, production projections and to avoid unnecessary maintenance by using preventive maintenance features.

Distinct Features of Alteem’s IIOT platform for Plastic Print and Packaging industry

No Requirement of data loggers

No requirement of Wifi connectivity near the machine

No hard wiring required

Implementation of secure wireless technology

Implementation cost per machine is very less

Production and Productivity

Critical deviations in Machine

Job Change time and KPIs

Plant Conditions

Maximize Production

A smart, systematic packaging process will continuously monitor and analyze machines to make sure they are performing as per the required capacities:

Monitor Downtime

Manufacturers can virtually monitor the production-line to facilitate instant maintenance on machines when the sensors detect machine’s inactivity. This allows manufacturers to plan production to meet product delivery timelines.

Enhance decision-making and root-cause analysis

loT’s graphical representation of the data collected from all the machines/devices provides clear information about the performance regarding the particular jobs going on, and those completed. These reports can be exported to excel or pdf.

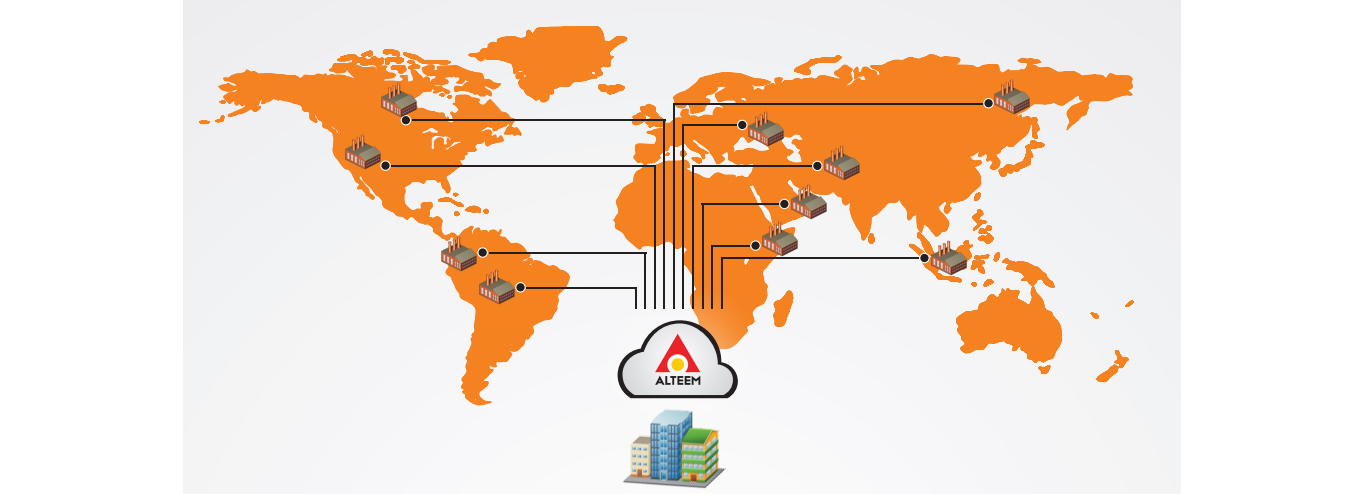

Constantly track KPls

The data collected from loT-enabled machines shall be collected on a cloud server and can be accessed at any time. This shall give the supervisor a clear idea of the machine’s usage patterns to check whether it is being utilized as desired, within the machine’s ideal capacities. If any discrepancies are observed, the operator can immediately call them out and correct them.

Remotely supervise for faster solutions

The user friendly Alteem Dashboard helps to obtain data in real time and know which jobs are in process or which ones are already done and how, in any production process. This data can be accessed through indicators, notifications, and PDF reports, once the job orders are finished. Also, statistics and incidences can be checked.

Plastic Printing And Packaging industry

- Rotogravure Printing Machine

- Flexo Printing Machine

- Slitter Machine

- Pouching Machine

- Blown Film Plant

- Lamination Machine

- Coating Machine

Woven Sacks

Industry

- Looms

- Tapelines

- Lamination Extrusion Machines

- Flexo Printing

Paper

Industry

- Paper Industry

- Printing Machine

- Coating Machine

- Paper Mill

Label

Industry

- Label Industry

- Label Printing Machine

- Coating Machine

- Label Slitting – Inspection Machine